- Universal Balancers

- Belt Drive Balancer

- Universal Joint Drive Balancer

- Universal Joint & Belt Drive Balancer

- Single-Plane Vertical Balancer

- Cross Flow Fan Balancer

- Axial Flow Fan Balancer

- Double-Plane Vertical Balancer

- Drive Shaft Balancer

- Auto-Positioning Balancer

- Self-Driven Balancer

- Special Balancing Machine

- Measuring Unit

- Automatic Balancers

- Vertical Drilling Automatic Balancer

- Vertical Milling Automatic Balancer

- Rotor End Surface Drilling Automatic Balancer

- Wound Armature Automatic Balancer

- Generator Rotor Automatic Balancer

- EV Motor Automatic Balancer

- Treadmill Motor Automatic Balancer

- Crankshaft Automatic Balancer

- Roller Automatic Balancer

- Two-station Motor Rotor Automatic Balancer

- Brake Disc Automatic Assembly Line

- Wheel Hub Automatic Assembly Line

- Auto Parts Industry

- Fan & Air Conditioning Industry

- Motor Industry

- Pump Industry

- Home Appliance Industry

- Machine Tool Industry

- Railway Industry

- Marine Industry

- Textile Industry

- 3C Electronics Industry

- Aviation & Aerospace Industry

- Grinding Tool & Abrasive Industry

- Fitness Equipment Industry

- Papermaking Industry

- Roller Industry

- Assembly Line

- Detection & Assembly Equipment

+86-21-39972151

-

Four-Station End Surface Drilling & Milling Automatic Balancer

Four-Station End Surface Drilling & Milling Automatic Balancer It is applied to the unbalance measurement and correction of rotors and EV motor rotors that require weight removal on end surface, and can integrate with rotor assembly line to achieve automatic production....

View detailed + -

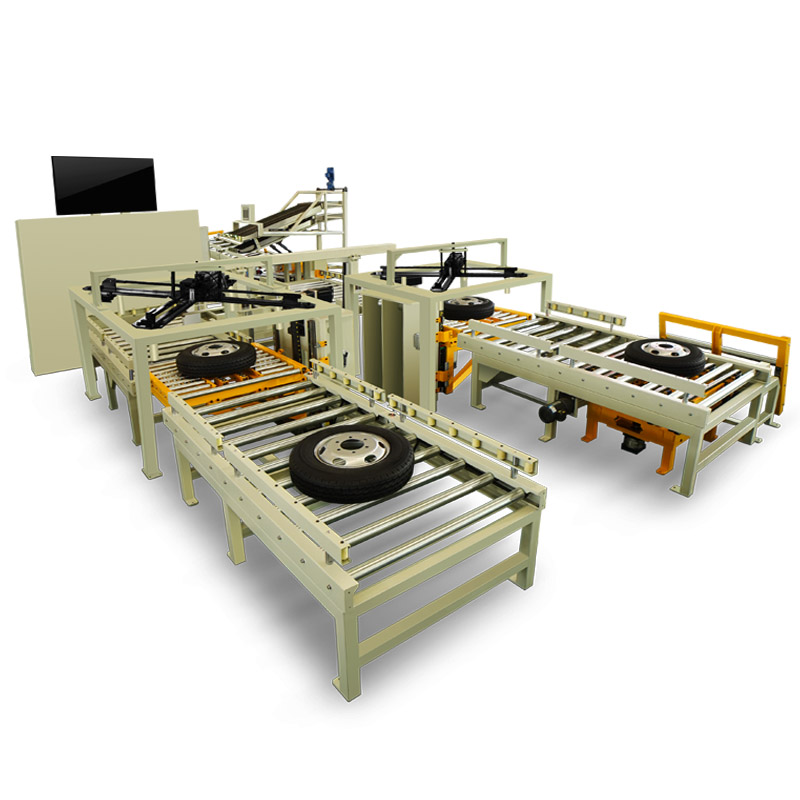

Automatic Tire Double Assembly Line Balancer

Automatic Tire Double Assembly Line Balancer It is used for the unbalance correction of automobile tires...

View detailed + -

Automobile Lidar Rotor Assembly Balancer

Automobile Lidar Rotor Assembly Balancer Technical data at a glancePRZS-0.3PRZS-1.1Max Mass of Workpiece (kg)0.31.1Max diameter of Workpiece(mm)4080Min Achievable Residual Unbalance Amount (emar)0.15g· mm/kg0.15g· mm/kg...

View detailed + -

Two-station Crankshaft Automatic Balancer

Two-station Crankshaft Automatic Balancer It is widely used in the balance correction of various automobile crankshafts, diesel engine crankshafts and small crankshafts in various industries....

View detailed + -

Cross Flow Fan Assembly Balancer

Cross Flow Fan Assembly Balancer It is suitable for the overall balancing of the cross-flow fan...

View detailed + -

Large-sized Single-plane Vertical Balancer

Large-sized Single-plane Vertical Balancer Vertical balancing machine is suitable for dynamic balancing test of large disc-shaped workpieces such as wheelset and brake disc of power locomotive. Beside, the weight removal device can be equipped as customer’s request...

View detailed + -

Large-sized Universal Joint Drive&Belt Drive Balancer

Large-sized Universal Joint Drive&Belt Drive Balancer This machine is widely used in the unbalance detection of mechanical rotating parts of large-sized motors, rubber rollers, water pumps, centrifuges, fans, crankshafts etc...

View detailed + -

Oversized Universal Joint Drive Balancing Machine

Oversized Universal Joint Drive Balancing Machine It is used for the unbalance correction of rotating workpieces such as large and medium-sized motor rotors, blowers, centrifugal impellers, drying cylinders, and rollers....

View detailed + -

Large-sized Belt Drive Balancer

Large-sized Belt Drive Balancer Used for the unbalance correction of rotating workpieces such as various large and medium-sized motor rotors, impellers, crankshafts, rollers and shafts etc....

View detailed +